New Tech for 150 TPD Maize Grits and Flour Milling

www.immyhitech.com www.immy.cn

The processing process of corn determines the competitiveness of enterprises, and the production cost, the stability of finished product quality and the comprehensive

utilization rate of by-products are indispensable! We focuses on the research and development and manufacturing of corn and grain engineering equipment, breaks the

limitations of the traditional process, developed a high-quality, high-efficiency corn grits and flour innovative process, to bring the industry a better quality corn processing solutions!

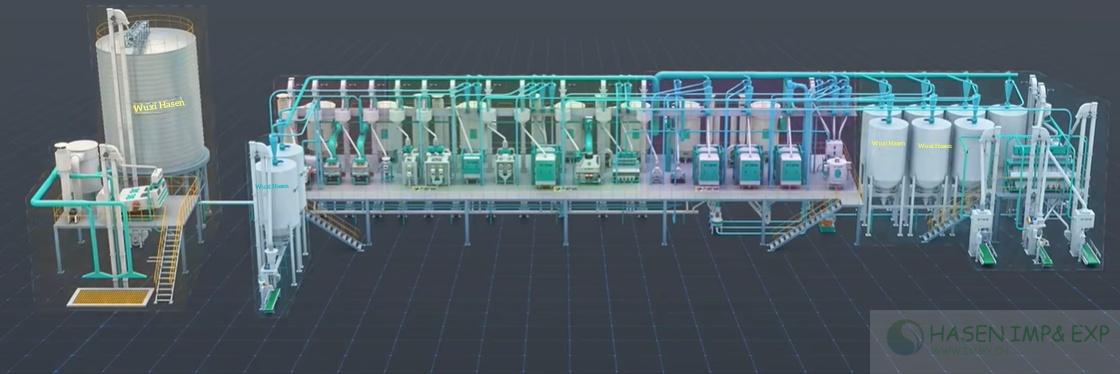

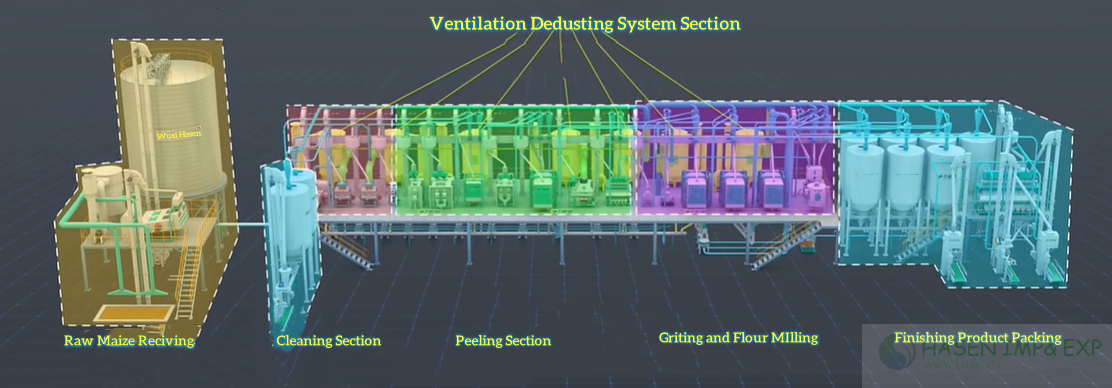

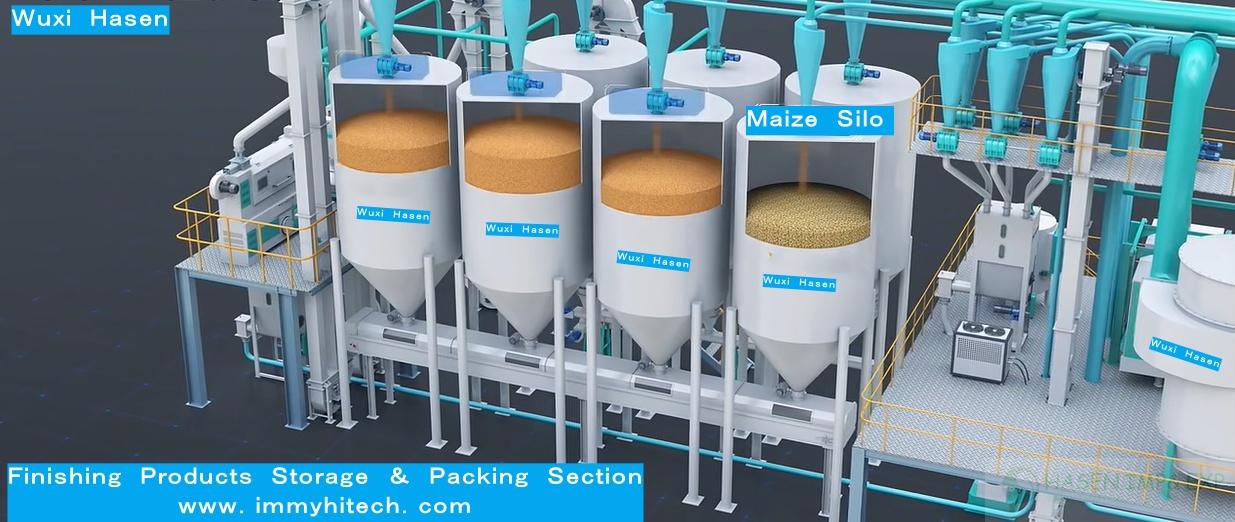

Daily processing 150 tons of corn grits and flour innovative process, designed as a two-layer platform structure, three-layer equipment arrangement, total length of 48m, width 8.0m,

height 10m, total installed capacity of 520kw, ton of material power consumption of about 50 degrees, grits and powder yield ≥ 65, grits visually observed within the no skin, no black

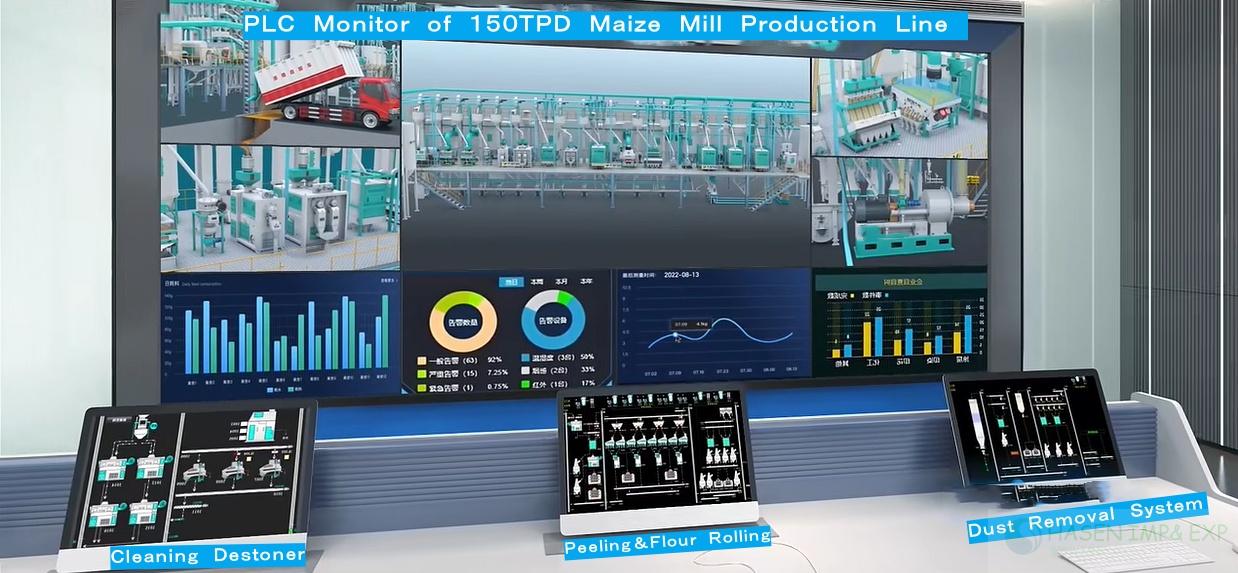

stars, no gluten in the powder, far more than the national standard. Equipped with PLC intelligent control, it can realize intelligent, digital, visualized and paperless production.

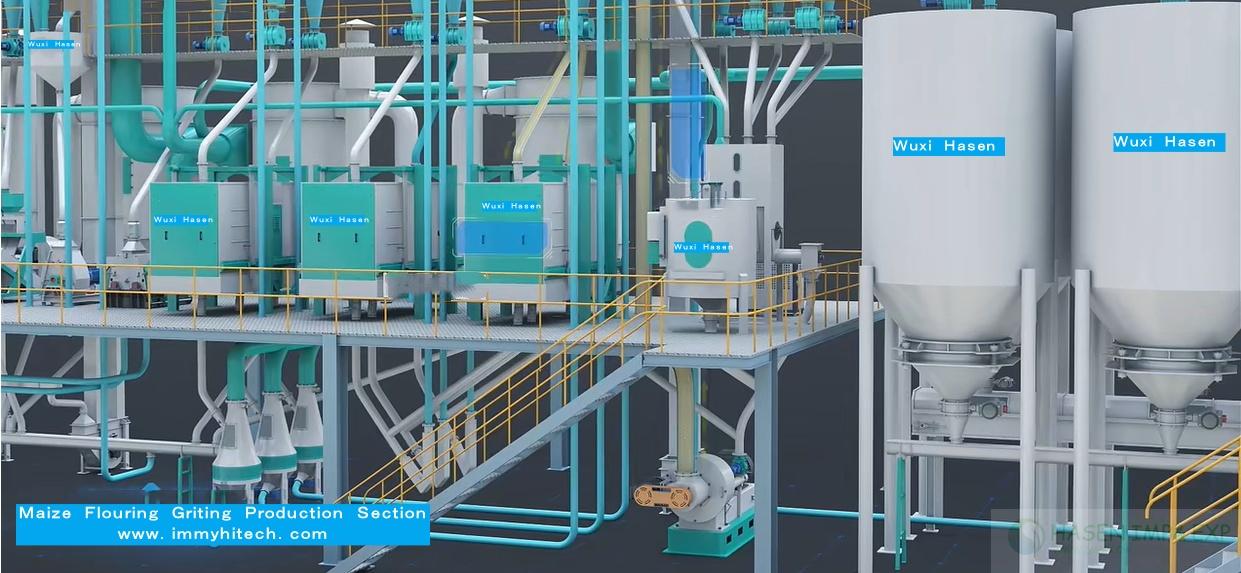

This innovative process adopts advanced technology and equipment, which can realize the efficient transformation from corn raw material to fine grits powder. Through the precise

grinding and screening system, it improves the crushing precision and separation effect of corn, and produces grits powder with uniform particles and fine texture.

The drive system and control system of this set of equipment have been optimized, which can greatly reduce the energy consumption and failure rate, and improve the operation efficiency

and stability of the equipment; meanwhile, it reduces the cost of production, and allows the enterprise to take the advantage in the market competition.

ADVANTAGE OF OUR MAIZE FLOUR&GRITS MILL PRODUCTION MACHINE LINE:

1、Numerical intelligence: the production line can realize intelligent, digital, visualization of continuous production, to protect the dust, explosion-proof, food safety standard requirements.

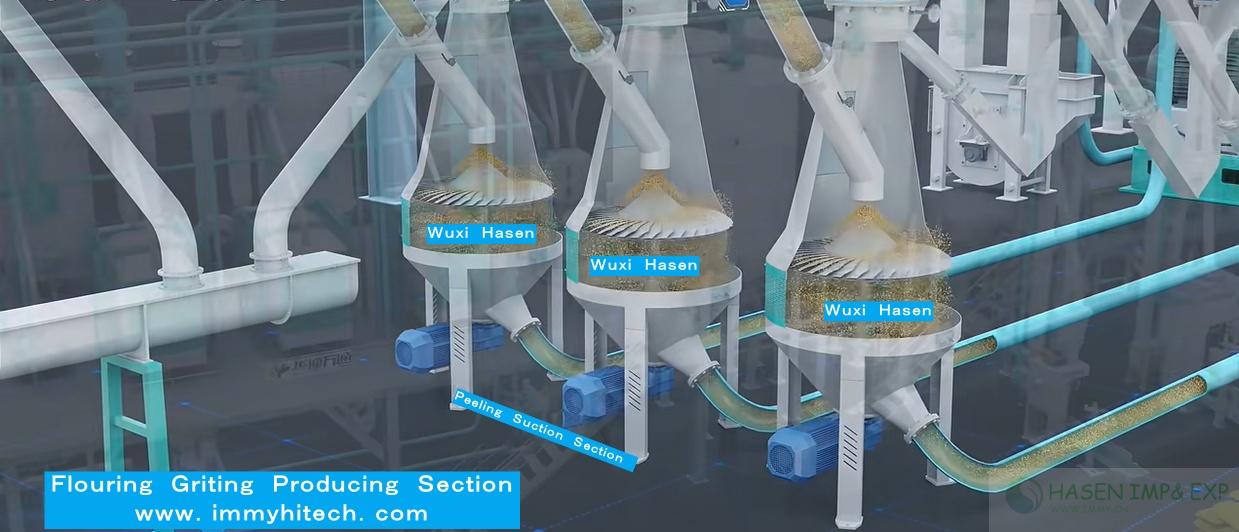

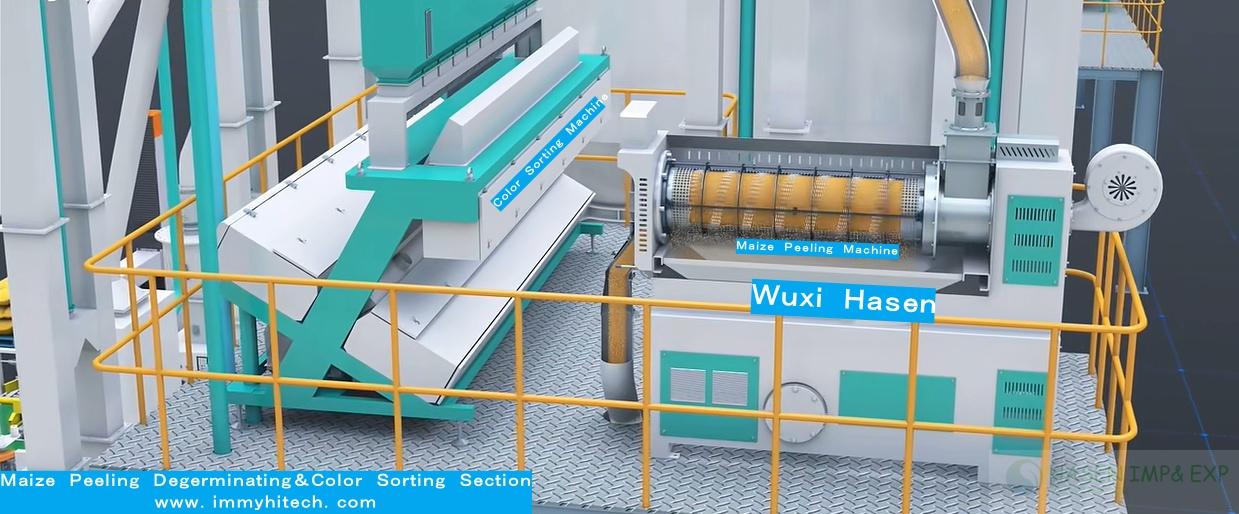

2、Specialization:the process with two special low energy consumption micro-crushing C-type sand roller peeling machine, the machine is only responsible for peeling, peeling corn skin with a

B-type sand roller de-embryo after the process to achieve low energy consumption and high peeling in addition to the role of germ.

3, high efficiency: peeling and de-embryo after the mixed kernel into the No. 1 square sieve out of the middle size kernel no embryo no black spot can go to the system, the sieve is not de-embryoed

large kernel accounted for 30% of the kernel and then into the low energy consumption of the short body of an iron roller to break the ballast de-embryo machine, two de-embryoed and then into the

No. 2 square flat sieve, No. 1, No. 2 screen containing a mixture of broken embryo kernel into the selection of embryo machine, color selector purified kernel with a large, medium kernel combined

with the grits. The advantage of this section is that the kernel of intermediate particle size is no longer enter the next stage of peeling, but directly making grits or powder to avoid repeated damage

affecting the yield. The perfect combination of micro-crusher and short-bodied iron roller ballast breaker and de-embryonizer increases the net kernel yield and reduces power consumption.

In the field of corn processing, it has been the leader of innovation. Choosing us is choosing the leading, choosing the quality, choosing the success. We will continue to optimize

and improve the corn processing technology, and promote the green and efficient development of corn deep processing industry with technological innovation.

For mroe information please cosulte with our engineer on line or E mail us at: amina@immyhitech.com

Thanks!

For WUXI HASEN GRAIN OILFEED FLAK MILLING PROJECT TEAM

Please check video of this project in youtube.com:

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:amina@immyhitech.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000