Application of Flour Blending in Wheat Processing-1

Edit by: www.immy.cn www.immyhitech.com

.png?x-oss-process=image/resize,w_100/quality,q_100)

Flour blending is more and more widely used in wheat flour mills, and the purpose of flour blending, the characteristics of flour blending process, the method of flour blending, the common equipment of flour blending and positive pressure conveying are introduced, which provides a reference for the design of flour mill flour mill flour blending process.(www.immy.cn)

Flour blending refers to the basic flour produced after several different components and characteristics after wheat blending, according to its precision index (ash, fineness, pink bran star, etc.) and quality indicators (wet gluten content, stability time, drop value, water absorption, evaluation value, etc.), and at the same time evenly add various flour enzyme preparations or nutritional enhancers to produce a special flour for food that meets the quality of finished products and other requirements.

1,The purpose of flour with flour

With the development of society and economy and the progress of food industry technology, people have put forward higher requirements for the quality and variety of wheat flour, and pay more and more attention to the practicability and quality stability of wheat flour, so the production of special flour and flour technology is particularly important in the post-processing of flour.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Wheat flour is the main basic raw material for making food, and with the development of economy and the progress of food industrialization, the requirements for the diversity, specificity and stability of wheat flour are getting higher and higher. However, due to the differences in regions, varieties and planting, there are large differences in wheat varieties and quality in various places, even in the same region, there are large differences, and then there are unstable factors such as moisture regulation, operation, start-up and shutdown, and machine failure in flour production, resulting in poor stability of flour quality and poor practicability. Although the application of wheat blending and high-precision flour processing equipment has improved the production quality of flour to a certain extent, it is still not perfect, and the application of flour blending technology can achieve good results(www.immy.cn).

In the production of special flour, in order to change the wheat variety infrequently, achieve stable operation, improve production efficiency, and the purpose of flour matching and uniform addition of flour improver and nutrient enhancer, a flour bulk storage bin is required for storing basic flour. At the same time, the flour bulk storage warehouse, flour mixing bin and packing bin are used to meet the requirements of night production (cheap electricity) and daytime packaging, and improve labor conditions. In the production of high-grade powder, in order to maintain product quality consistency, powder blending technology can also be used to achieve the purpose of stable quality.

Therefore, the purpose of flour blending is to process several single varieties of wheat separately to produce several basic flours with different precision and different qualities according to the quality of special flour, especially the requirements of the rheological properties of flour, through appropriate proportions, to prepare various special wheat flours. At the same time of powdering, various improvers, nutritional enhancers and so on can be added.

2,Characteristics of the powder mixing process

From the analysis of the actual situation of China's milling plants, most manufacturers only produce a part of the special powder on the basis of grade powder, and it is a packaged finished product, which does not have the function of bulk and bulk transportation, so the powder mixing process should have the following characteristics:

(1) The process should be flexible and changeable, mainly based on the packaging of grade powder, and then carry out the powder preparation process when it is necessary to prepare special powder.

(2) It should have the functions of micro addition, secondary mixing and reversing.

(3) The powder bin should be mainly powdered, taking into account the scattered storage function, so the warehouse capacity does not need to be large, and the quantity can be a little more, so as to achieve the purpose of flexible powder blending. Generally, the capacity of the powder bin should be 1~3 days of production capacity.

(4) The total output of the powder blending process of the grade powder plant can be designed to be smaller, because there is usually less powder blending, such as the output design is larger, which will cause waste in equipment selection, power consumption, floor space and other aspects(www.immy.cn).

.png?x-oss-process=image/resize,w_100/quality,q_100)

In recent years, production lines for the production of special powders have also been continuously built or renovated. This kind of production line should use more powder mixing bins, larger bin capacity, generally should have a warehouse capacity of 5~15 days (due to the large warehouse capacity, you can use less or less finished product warehouse, and directly load the palletizer after supporting packaging), in order to facilitate a variety of powder preparation, accurate powder preparation.

There are roughly two forms of material transportation in the powder preparation section. One is the bucket elevator to lift the material, the screw conveyor to transport the material horizontally, the outstanding advantage of the method is that the equipment is reliable, equipped with power saving; The disadvantage is that it occupies a large area, and this form is suitable for small flour mills. The other form is positive pressure pneumatic conveying of materials, and the materials are directly sprayed into the powder mixing silo with roots blower, which is simple and applicable, covers a small area, has no residue, but consumes a large amount of power. It is often used by some large factories or mills that have later transformation and flour blending.

3,The method of mixing powder

First of all, the flour of different quality and different grades produced in the milling room is sent to different storage silos through conveying equipment for storage, and these flours are called basic flour. Before the base flour is put into the warehouse, it must go through the processes of flour inspection, measurement, magnetic separation and so on.

When it is necessary to mix flour, several varieties of basic flour that need to be matched are released from the silo, mixed together according to a certain proportion, and various additives are added as needed, and after stirring and mixing, it becomes finished flour. According to the different types of base flour, the proportion of various base flours and additives, different grades or different types of special flour can be prepared.

There are various forms of powder blending, but the overall can be divided into two types, namely volumetric type (also known as coarse Flour) and gravimetric type (also known as fine flour).

The process of coarse flour blending is simple, and the precision of flour blending is low, which is suitable for simple flour matching and the addition of a small amount of additives. The process is usually as follows: bulk silo → speed-regulating screw feeder→ flour screw conveyor→ flour inspection and screening → insecticide → product metering and packaging machine.

The process of fine flour blending is more perfect, and its flour blending accuracy is higher, which is suitable for preparing special flour, nutritionally fortified flour and pre-mixed flour with high grades. The production process is usually as follows: raw powder silo → screw feeder→ flour bin→ flour weighing (batch weighing, medium weighing and micro weighing→), mixer→ buffer bin (packing bin→), flour inspection and screening→ insecticide → product metering and packaging machine.

According to the needs of the user market, large flour mills will consider that coarse flour and fine flour can be realized in a flour mixing workshop in the process design stage, and can be packaged with simple flour or fine flour through dial control and adjustment.

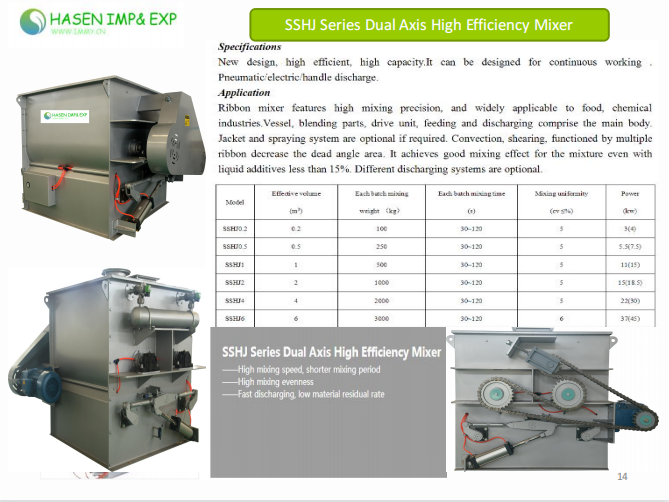

4,Common equipment for powder blending

Flour mixing and post-processing equipment mainly includes: flour mixing silo, spiral feeder, powder mixing scale (batch weighing, medium weighing), vibrating silo bottom discharger, insecticide and trace element addition machine, etc.

4.1 Powder bin

4.1.1 Structure of the powder bin

The powder bin is generally composed of the silo body and the bottom of the silo.

The cross-section of the powder bin should be as close to a square as possible, the side length is generally 2.5~4.5 m, and the height of the bin is generally 8~22 m (the diameter of the packing bin is generally 1~3 m, and the height of the bin is 3~10 m). If the silo section is too small or the silo body is too high, the flour in the silo may be easy to arch.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:amina@immyhitech.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000