Application of Flour Blending in Wheat Processing-3

Edit by: www.immy.cn www.immyhitech.com

When the material particles fall freely in the boundary, still air, due to the action of gravity, the falling speed gradually accelerates, and at the same time, the air resistance of the particles also increases, and finally when the air resistance increases to the same as the buoyancy weight of the particles (the difference between gravity and buoyancy), the material particles fall at the same speed, and the constant falling speed is called the sedimentation speed of the particles(www.immy.cn).

Conversely, if the particles are placed in a vertical upward air stream, if the velocity of the air flow is less than the sedimentation velocity of the particles, the particles in the air stream will fall; If the velocity of the air flow is greater than the sedimentation velocity of the particles, the particles will rise with the airflow, that is, the pneumatic conveying state will be formed; If the velocity of the air flow is equal to the sedimentation velocity of the particles, the particles will be in a certain position and neither rise nor fall, that is, they will be in a suspended state, and the velocity of the air flow at this time is the suspension velocity of the particles.

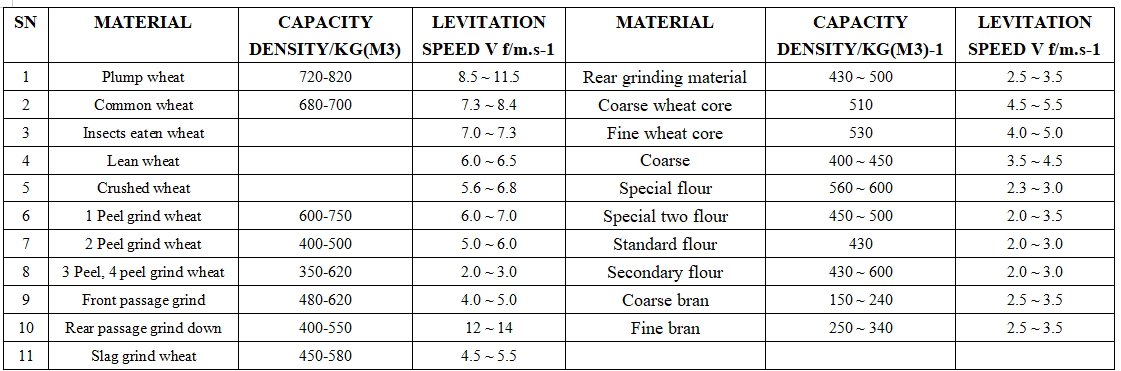

Suspension velocity of wheat and work-in-progress is shown in Table 1.

5.1.2 Positive conveying air velocity and material movement state

In the process of positive pneumatic conveying, the movement state of material particles is mainly controlled by the conveying air velocity. When the conveying volume is constant, the greater the conveying airflow velocity, the closer the particles are evenly distributed in the pipeline, and they are in a completely suspended conveying state;

When the airflow velocity gradually decreases, the vertical pipeline will have a decrease in particle velocity and uneven material distribution, while the horizontal conveying pipe will be denser and denser the closer to the bottom of the pipe. When the airflow velocity is lower than a certain value, the vertical pipe will have a local pipe section material drop phenomenon but can be lifted, and for the horizontal pipe, a part of the particles will stagnate at the bottom of the pipe, and be in a state of movement where it slides and is pushed by the air flow at the same time.

When the airflow velocity is further reduced, the stagnant material layer at the bottom of the horizontal conveying pipe moves unsteadily, and finally stops, resulting in pipeline blockage, while the vertical conveying pipe appears the phenomenon of instantaneous settlement of materials in the pipeline, resulting in pipeline blockage.

In vertical conveyors, aerodynamic forces play a direct role in the suspension and conveying of materials. The aerodynamic force is on the same vertical line as the gravity of the material particles, but in opposite directions. Because the material is in the turbulent airflow, the particles are affected by the radial component, and at the same time, due to the irregularity of the particles themselves and the Magnus effect caused by the collision and friction between the particles and the inner wall of the pipeline, the particles will be subjected to the force perpendicular to the direction of the airflow. Thus, in the vertical pipe, the material moves upwards in an irregular curve.

5.1.3 Airflow velocity distribution of the conveying pipe section

When a pure air pipe flows, the velocity has a maximum value on the axis of the pipe and is symmetrical to the axis of the pipe. When there is a flow of material mixed in the air, i.e. in the pneumatic conveying pipe, the distribution of the air velocity varies greatly. In horizontal pipes, due to the gravitational action of the particles, the material distribution becomes denser the closer to the bottom of the pipe, so that the position of the maximum speed is moved above the axis of the pipe. The lower airflow velocity at the bottom of the pipe will lead to a decrease in the velocity of the particles, and finally affect the transportation of the material, and in severe cases, the material will stagnate at the bottom of the pipe and the pipeline will be blocked.

5.1.4 Pressure loss characteristics of pneumatic conveying

.png?x-oss-process=image/resize,w_100/quality,q_100)

When the material particles are transported in a suspended state in the pipeline, there is always a collision or friction between the particles or the pipe wall, which will cause the particles to lose part of the energy obtained from the air flow, that is, a part of the energy of the air flow will be consumed on the collision or friction between the particles and the pipe wall. And this part of the energy loss is expressed in the form of pressure loss in the airflow. In general, the greater the air velocity, the more significant the pressure loss; When the air velocity decreases, the particles will stagnation, which will aggravate the friction between the particles and the pipe wall, and the pressure loss will increase.

For materials with roughly the same bulk density and surface roughness, the wider the particle size distribution, the greater the pressure loss. When the particle size is different, its velocity, number of collisions, acceleration and other motion conditions are different. Small-sized particles are more likely to accelerate than large-sized particles, so there are more small particles catching up from behind, and small-sized particles are more likely to chase and collide with large-size particles. Therefore, particle collision will lose a part of the kinetic energy of the particles. In addition, the vortex generated after the large particle size particles may also be involved in the small particle size. As a result, the movement of the particles is more irregular, resulting in increased pressure loss.

.png?x-oss-process=image/resize,w_100/quality,q_100)

6,Summary

Looking back on the development history of wheat milling and flour blending in China, with the continuous improvement and perfection of grinding and sieving and milling equipment, wheat milling from stone mill to roller mill, from "repeated grinding" to "gradual grinding", the milling process strictly follows the principle of "homogeneous merger, step-by-step pushing", and the basic principles of wheat processing have always run through it. The powder is also made from scratch, from coarse powder to fine powder.

According to the market demand, adjust the powder blending process, reasonably select the fine and crude blending processes, and improve the quality and market competitiveness of special powder. With the continuous increase in the price of raw materials, the cost pressure of flour mills will be greater, and the transformation of milling and flour blending process to energy saving, environmental protection and low carbon is the only way in the future.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:amina@immyhitech.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000