Feb 05, 2024

Exploration of key points of

wheat processing technology and

Application of online detection technology-2

Prepared by: www.immy.cn

Analyze the key points of the whole process of wheat processing technology, discuss the application of online detection technology in the milling process, and apply the online detection technology to realize the upgrading of wheat flour processing technology, which can improve production efficiency, realize production data, and ensure the stability of wheat flour product quality.

In recent years, the competition in the wheat flour industry has become more and more fierce, most wheat flour processing enterprises continue to build and expand modern wheat flour milling production lines, how to strive for a limited market share, will determine the survival and development of wheat flour processing enterprises.

In order to ensure the further expansion of the market share of wheat flour processing enterprises, the key is that the quality of wheat flour is stable, the product meets the market demand, and is recognized by consumers.

At present, the wheat flour processing industry has realized intelligent wheat flour processing, and fully automatic intelligent wheat flour processing plants have appeared in China, which have realized real-time online collection of characteristic parameter long passsage data of raw grains, intermediate materials, and wheat flour, and fused various sensor information to form intelligent control decisions, so as to complete intelligent control and automatically adjust the equipment and process parameters in the process

However, more wheat flour processing plants in China have only achieved "semi-automatic production", such as automatic start and stop of equipment, PLC control system collection, display of some simple production information and production data, etc.

In the production process, the technical personnel on duty in the workshop are required to continuously adjust the equipment status and process parameters in the production process according to the characteristic parameter information of raw grains, intermediate materials and wheat flour obtained by regular sampling and offline detection by inspection and laboratory personnel, but the regular sampling offline detection is generally sampling every few hours, and the manual detection time is longer, resulting in the lag of the detection results, or it is difficult to find the quality problems that occur in the middle of the two sampling, resulting in unstable product quality.

For wheat flour processing plants that produce special flour, multi-variety raw grains and multi-variety products, it is particularly important to ensure the stability of wheat flour quality in the process of wheat flour processing, how to ensure that different varieties of raw grains or semi-finished products are mixed together when transferring warehouses and entering and exiting warehouses, and how to avoid fluctuations in product quality due to changes in equipment parameters or equipment failures.

On-line testing equipment and instruments

At present, the advanced online testing equipment on the market includes: near-infrared online detector, ultrasonic online detector, online color and bran star detector, online particle size detector, etc., which can meet the detection of moisture, whiteness, protein, wet gluten, sedimentation value, hardness, ash, water absorption, damaged starch, bran powder and particle size.

1.1 Near-infrared (ultrasonic) online detector

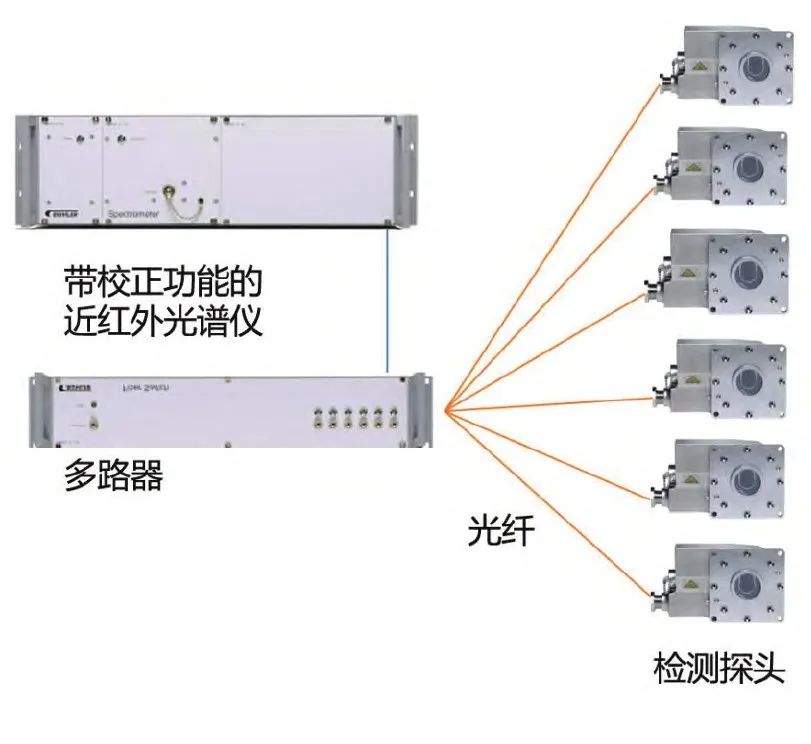

Figure 1 shows the NIR spectroscopy, which uses NIR (ultrasonic) technology and digital photography technology to quickly detect key indicators in wheat or wheat flour in real time, such as moisture, protein, ash, particle size, whiteness and damaged starch (as shown in Tables 1 and 2)

Working principle: Use 850~1 650 nm near-infrared light wave or ultrasonic wave to scan wheat or wheat flour, transmit the signal to the spectrometer through optical fiber, the spectrometer analyzes the signal, and the NIR software calculates and analyzes the results of the test items, which can establish a quality database and realize quality traceability.

1.2 On-line detection particle size analyzer

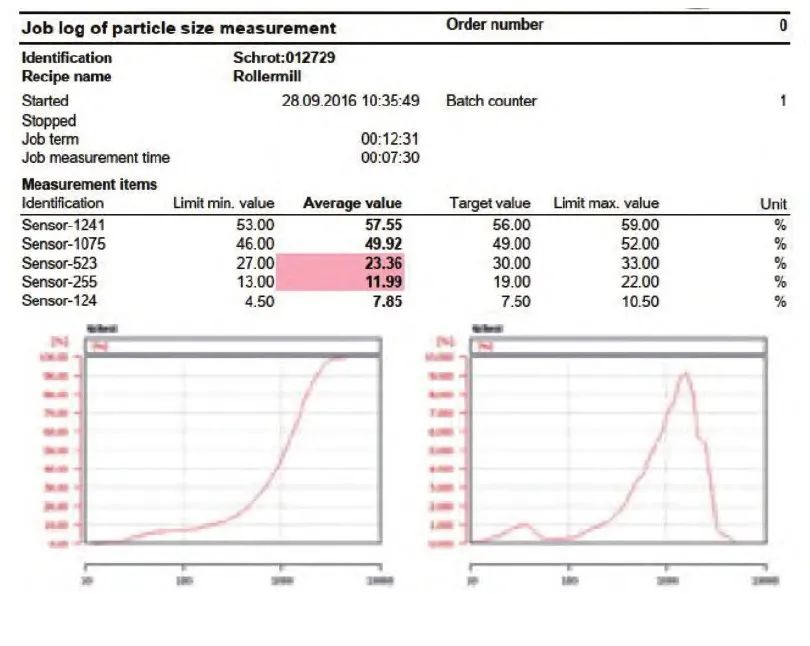

Figure 2 shows the in-line particle size tester. The instrument is a two-in-one detector with laser diffraction and camera functions. Among them, the bypass sampling tube can be used or automatic sampling, and the automatic discharge pipe can be automatically discharged. The specific instrument parameters are shown in Table 3, and the test data examples are shown in Figure 3.

Working principle: The sampling mechanism transports the material to the laser and camera detection area after sampling. It is first tested in the laser diffraction zone, then by the camera detection zone, and then the tested material sample is sent back to the main stream of the material.

The proportion of material in different screen configurations can be provided and compared with the set value. In the process of wheat milling, the peeling rate of B1, B2 and other skin milling systems can be set and monitored in real time.

1.3 Online bran star whiteness detector

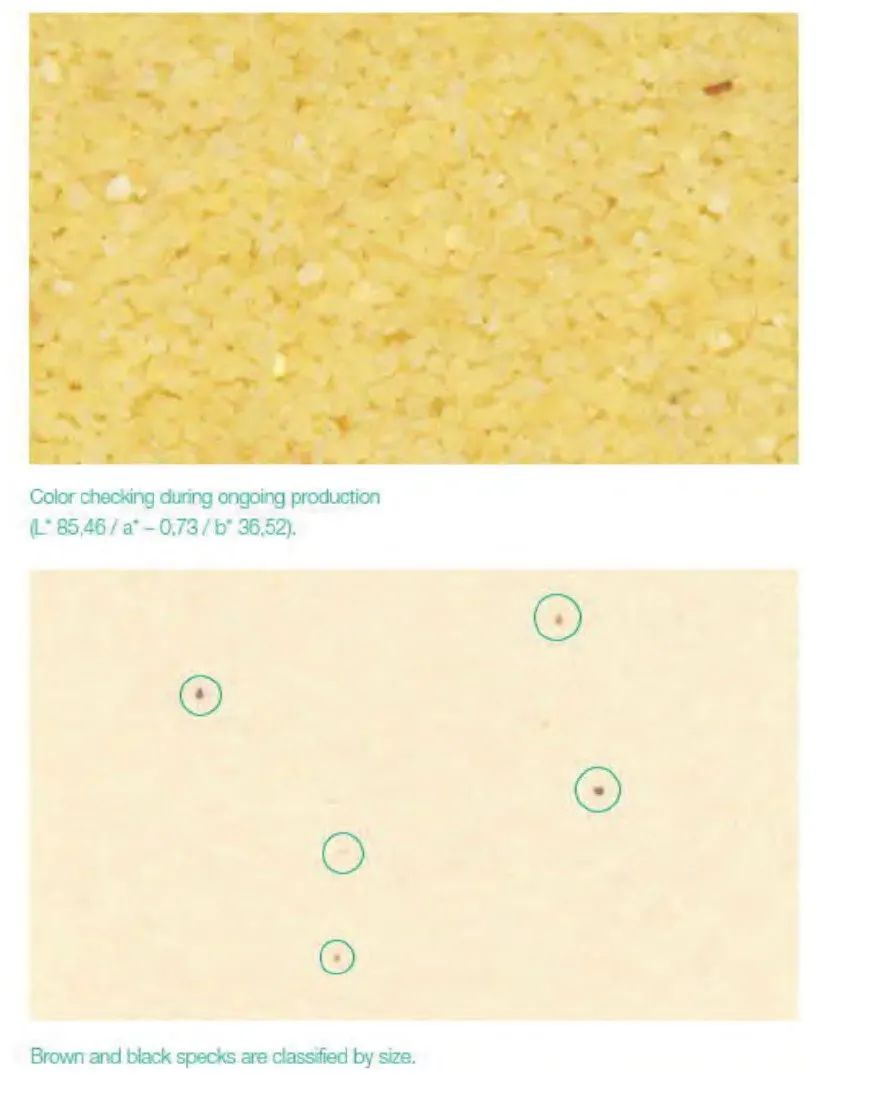

The monitoring image of the online bran whiteness detector is shown in Figure 4. Principle: The Pink Bran Detector is an integrated vision system consisting of a computer and LED light source and a color camera. The system integrates a database of color reference values that compensate for fluctuations in the object and ambient temperature, light source and camera aging, and a uniform color calibration to ensure consistent results for each sensor.

The system evaluates the pink color of flour through the image processing function of the computer, and the pink values are selected from L*, a*, and b* values in the CIE 1976 color space, which can also be converted into domestic whiteness values, and the system can classify and count the number and species of bran stars (Figure 4).

Key points of wheat flour processing technology

There are some critical control points in the wheat flour processing process (Figure 5), and the critical control points are monitored by advanced online testing equipment to ensure the stability of wheat flour quality.

2.1 Control of raw grains processed from wheat flour

Wheat grains are rich in starch, more protein (generally 10%~15%), a small amount of fat, and a variety of minerals and vitamins. The content and quality of proteins, especially gluten proteins (mainly gliad in and gluten in), play a decisive role in quality [2]. Modern wheat planting, the quality of varieties is relatively stable, but wheat from the harvest to enter the processing workshop, will go through many turnovers, there may be mixed wheat, impurities or artificially maliciously mixed inferior wheat, etc., if only through the naked eye judgment or through manual spot check of raw grain testing is qualified, it is possible to cause the quality of raw grain and the actual quality of the need to be very different, thereby causing the quality of flour to be unstable at the source.

Therefore, the near-infrared online detector can be applied to scan the wheat with the near-infrared light wave, and the detection items can be analyzed by the spectrometer, and the results can be quickly analyzed in only 1 s (as shown in Figure 6), and the quality fluctuations of wheat can be detected in time, and it can be sorted, returned or reduced. Through the online configuration of hardware facilities, the quality data of raw materials can be monitored in real time throughout the whole process, so as to facilitate the subsequent accurate use and ensure the stable raw materials for product quality.

2.2 Combination of wheat raw grains

Most of the wheat flour processing plants that produce special flour, because the inherent characteristics of each wheat are difficult to meet the production of special flour, they will develop the corresponding formula according to the characteristics of the wheat raw grain to produce the desired special wheat flour, which is convenient for the accurate matching production of the subsequent process, but there will be the following problems:

the accuracy of the wheat mixing scale used in the matching of wheat raw grain is relatively poor or malfunctioning, resulting in deviation;

the raw grain inside the original grain silo will be automatically graded,

(3) There may be mixed wheat when the raw grain is received, resulting in the quality of the raw grain fluctuating, the matching effect is not ideal, and the stability of product quality is not guaranteed. Therefore, the equipment after the wheat is equipped with a near-infrared online detector, the problem can be found in time, the corresponding equipment or wheat is inspected and analyzed, and appropriately adjusted and optimized, at the same time, under the condition of meeting the quality requirements of R & D, the proportion of wheat can be appropriately adjusted through the monitoring results, and the production cost of raw grain can be reduced,

such as the following cases:

In a domestic project, under the condition of certain raw grains, there are the following measured data (as shown in Figure 7), when the online detection technology is not used, the matching ratio is: the mass ratio of high-gluten wheat flour to low-gluten wheat flour is 50%:50%, using online detection technology, and timely adjustment, the matching ratio is: the mass ratio of high-gluten wheat flour to low-gluten wheat flour is 47.8%:52.2%, which can save 2.2% of the use of high-gluten wheat flour.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:amina@immyhitech.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000