Corn maize Peeler Peeling by Shaving not Grinding for maize(corn) plant, white wine factory, brewery, feed factory and maize(corn) germ separation equipment. www.immy.cn / www.immyhitech.com

CORN (MAIZE) PEELER

Corn maize Peeler Peeling by Shaving not Grinding for maize(corn) plant, white wine factory, brewery, feed factory and maize(corn) germ separation equipment. www.immy.cn / www.immyhitech.com

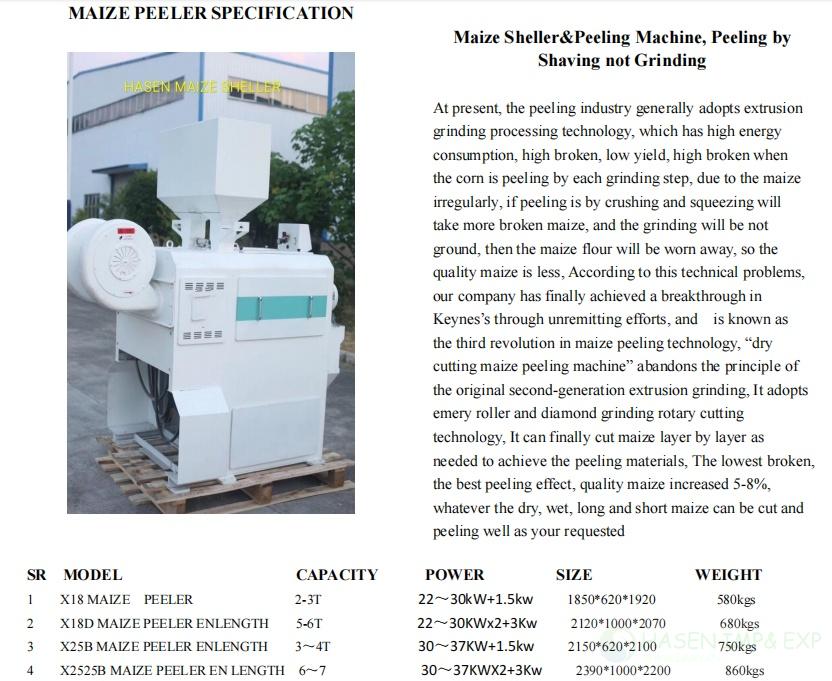

Maize Peeling Machine, Peeling by Shaving not Grinding

At present, the peeling industry generally adopts extrusion grinding processing technology, which has high energy consumption, high broken, low yield, high broken when the corn is peeling by each grinding step, due to the maize shape irregularly, if peeling is by crushing and squeezing will take more broken maize, and the grinding will be not ground, then the maize flour will be worn away, so the quality maize is less.

According to this technical problems, our company has finally achieved a breakthrough in Keynes’s through unremitting efforts, and is known as the third revolution in maize peeling technology, “dry cutting maize peeling machine” abandons the principle of the original second-generation extrusion grinding, It adopts emery roller and diamond grinding rotary cutting technology.

It can finally cut maize layer by layer as needed to achieve the peeling materials, The lowest broken, the best peeling effect, quality maize increased 5-8%, whatever the dry, wet, long and short maize can be cut and peeling well as your requested.

Side covers and built-in hopper for germ extraction made in stainless steel;

Rotor made of highly wear-resistant material;

Main shaft with special surface treatment against rust;

Built-in motor;

Machine structure made of weld steel sheet;

Control panel

Low percentage of grains with remaining skin;

High level of peeling;

High quality of peeling;

Low broken maize(corn) in the grains;

High oil content in the germ removed;

Excellent grain surface finishing without broken maize(corn).

X-18 and X 25 models series vertical corn(maize) peeling machine is suitable for corn peeling kernel plant, White liquor factory, brewery, feed factory and corn germ free equipment.

The new type of peeling machine is based on the principle of low rotating speed, kneading and impact, which reduces the rate of broken germ, improves the rate of whole kernel and the rate of kernel extraction.

APPLICCATION, WORKING PRINCIPLE AND PROCESSING FLOW

1.1 Uses

X-18D/X-25D low-temperature dry corn peeling machine, which is mainly used for corn peeling, rooting, black spots, and germ removal, is used in the factory process of feed and grain and oil enterprises.

1.2 How it works

The corn enters the machine from the feed hopper, is fed into the dehulling chamber by the screw propeller, and advances along the surface of the sand roller. This machine has a high air pressure, large air volume of the air jet fan, "strong air spray" through the hollow spindle, the sand roller of the air spray hole into the peeling chamber, in the sand roller, diamond grinding disc, rice knife and bump sieve under the joint action, accompanied by the high-speed rotation of the sand roller to produce a "vortex" to make the corn kernels flip, corn skin continuous and repeated double-sided "cutting" and "rubbing", so that it peeled, rooted, black spots, germ.

In the peeling process, the sand roller, diamond, bump sieve cuts the surface of the corn kernel to remove the skin layer, and the corn kernel in the peeling chamber will be rubbed and collided with a large amount of heat, which will increase the temperature of the corn kernel, resulting in the lakeing of corn starch (the temperature of corn starch lake is in the middle of 68~72 degrees), and the starch will lose polarization + word diagram. X-18D/ X-25D low-temperature dry corn peeling machine provides 2~3 times the air volume of the conventional peeling machine, which takes away a large amount of heat generated by cutting and friction, increases the bran discharge, inhibits or reduces the temperature of the corn kernels, strengthens the "self-rolling" and "mutual grinding" between the corn kernels, improves the uniformity of peeling, makes the corn kernels low temperature and less crushing.

X-18D/ X-25D peeling machine outlet adopts double pressure door closed air device, so that the pressure of the peeling chamber is uniform, the machine is equipped with suction at the inlet, and the rice outlet is equipped with suction cool rice trough, which improves the air efficiency of the peeling machine, realizes "dynamic cool rice", further reduces the meter temperature, reduces the power equipment and power consumption of the wind network of the peeling unit, and is an energy-saving low-temperature dry corn peeling machine

ADVANCED TECHNOLOGY

Adopts the most advanced technology and six equal parts of the shaving plate for centrifugal impact to achieve the principle of breaking kernels and germ extraction.

Performance, specifications and parameters of the equipment

2.1 Model X-18D/X-25D

2.2 Production capacity (KGH-1) 2000~3000 / 3000~4000

2.3 Air volume (m3h-1) 2200~2500 / 2500~3000

2.4 Static pressure (Pa) 2000~2500 / 2000~2500

2.5 Sand roller (diameter × length mm) Φ160×790 /Φ230×790

2.6 Screw propeller (diameter × length mm) Φ175×158 /Φ245×156

2.7 Radial gas storage (mm) 10

2.8 Axial inlet gas storage (mm) 2

2.9 Axial outlet gas storage (mm) 10

2.10 Jet fan power (kw) 1.5

2.11 Power(kw) 22(Motor Y180M-4) or 30(Motor Y180L-4) /

30 (Motor Y200M-4) or 37 (Motor Y200L-4)

2.12 Dimensions: L×B×H (mm) 1676×620×2148

Equipment structure:

X-18D/ X-25D low-temperature dry corn peeling machine is mainly composed of feeding hopper, peeling chamber, body, jet fan and discharging cold rice.

3.1 Feed hopper assembly

The feed hopper part is composed of a feed hopper, a ventilated feed hopper seat, a feed gate, and other components, which are fixed on the feed bearing seat.

For automatic control, the feed gate can be fitted with a cylinder.

WARNING:

The open access door cleans up bran powder and magnetic impurities, and it must be stopped!

3.2 Peeling chamber assembly

The peeling chamber is composed of a frame, a grinding roller spindle, a screw head, a grinding roller, a bearing seat at the feeding end, a bearing seat at the discharging end, a diamond grinding disc, a bump screen, a rice knife, a pressure door and other parts.

3.2.1 Diamond grinding discs and bump sieve discs

Diamond grinding disc, bump screen, for the long hole, the hole width is 1.3mm and 1.5mm, the installed factory is 1.3mm hole, (there are oblique holes, straight hole bump screen composition), the processing of corn varieties with high moisture should use 1.5mm hole width bump screen.

According to the direction of the opening hole, the screen is divided into straight hole screen, oblique hole screen, (straight hole screen, oblique hole screen and diamond screen are mixed to facilitate multiple directions cutting.

The installed factory peeling machine is 1.3mm straight hole screen and inclined hole, and the user can choose the screen hole according to the processing variety and moisture size.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:amina@immyhitech.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000