Flour packing machine paper bag line

Rotary bag feeding packaging machine,Paper Bag packaging machine, a digital bag packaging machine by quantitative weighing scale,gluing,sealing and packing machine line for wheat maize flour and starch etc. www.immy.cn / www.immyhitech.com

PAPER BAG FLOUR / BRAN/ STARCH PACKING MACHINE LINE

PAPER BAG FLOUR / BRAN/ STARCH PACKING MACHINE LINE

Rotary bag feeding packaging machine,Paper Bag packaging machine, a digital bag packaging machine by quantitative weighing

scale,gluing,sealing and packing machine line for wheat maize flour and starch etc. www.immy.cn / www.immyhitech.com

Equipment supply scope and technical requirements

(1). Rotary bag feeding packaging machine

Bag packaging machine, a digital bag packaging machine.

Just jog the bag width adjustment on the touch screen, and the device can automatically adjust the width of 8 pairs of grippers, without manually adjusting them one by one.

The equipment has a self-diagnosis display and self-maintenance system, if there is any abnormality in the equipment itself or the surrounding working environment, the system will alarm and display the alarm reason on the touch screen. Technicians can troubleshoot directly.

The equipment has a detection system, which truly realizes "bagless - no filling - no sealing, empty bag rejection", and the packaging yield is high!

The transmission cam of the packaging machine is a cam, which makes the transmission more stable, has a long use time, and the bearing is an imported bearing.

Packaging machine operation mode:

(servo) bag opening→→ unloading→ bag mouth dust removal→ (motor) vibration → vibration → bag mouth shaping →folding bag → shearing → bag mouth folding edge→ spray glue sealing→ shaping discharge→ counting and finishing sleeve→ heat shrinking discharge

Screw measuring machine with degassing mechanism

1, Technical parameters

(1) Flat bottom paper bag packaging machine (1KG or 2KG) single size bag

(2) Machine size: (length× width × height) 2800× 1300×1700mm

(3) Machine weight: 2500kg

(4) Performance: Packaging material: flat bottom kraft paper bag, flat bottom ordinary paper bag

Packaging: flour, sugar, milk powder, etc

Packaging bag form: flat bottom paper bag bag

Packing speed: 600-1000 bags/hour

Packing size: bag width: 100mm—120mm

Side width: 70mm—90mm

Bag length: 280mm—350mm

(5) Motor power: Main power: 1.5KW 4P AC380V

Vacuum pump power: 2.4KW 4P AC380V (1 set)

Glue sprayer power: 15KW 4P AC380V

(6) Motor: 1500W, speed ratio 1:30

(7) Intermittent mechanism: 125DS.-8-12-2L

(8) Vacuum pump: KVT6.0 type

(9) Overload protection device

(10) Specifications of air pump:

Exhaust pressure: 0.8mPa

Displacement ≥ 0.8m3/min

(11) Power supply: drive power supply AC380V

Control power supply DC24V

(12) Speed requirements: 1kg: 15-22 packs/min

(13) Packaging material: flour

The action of each component

The first station feeding bags to pack flour

2nd station open paper bag mouth

The third station filling

Fourth station Shake bag to tight up flour in bag

Fifth station Shake bag to tight up flour in bag

Sixth station Shake the bag to flour evenly in bag

Seventh station Drop bags

Eighth station empty

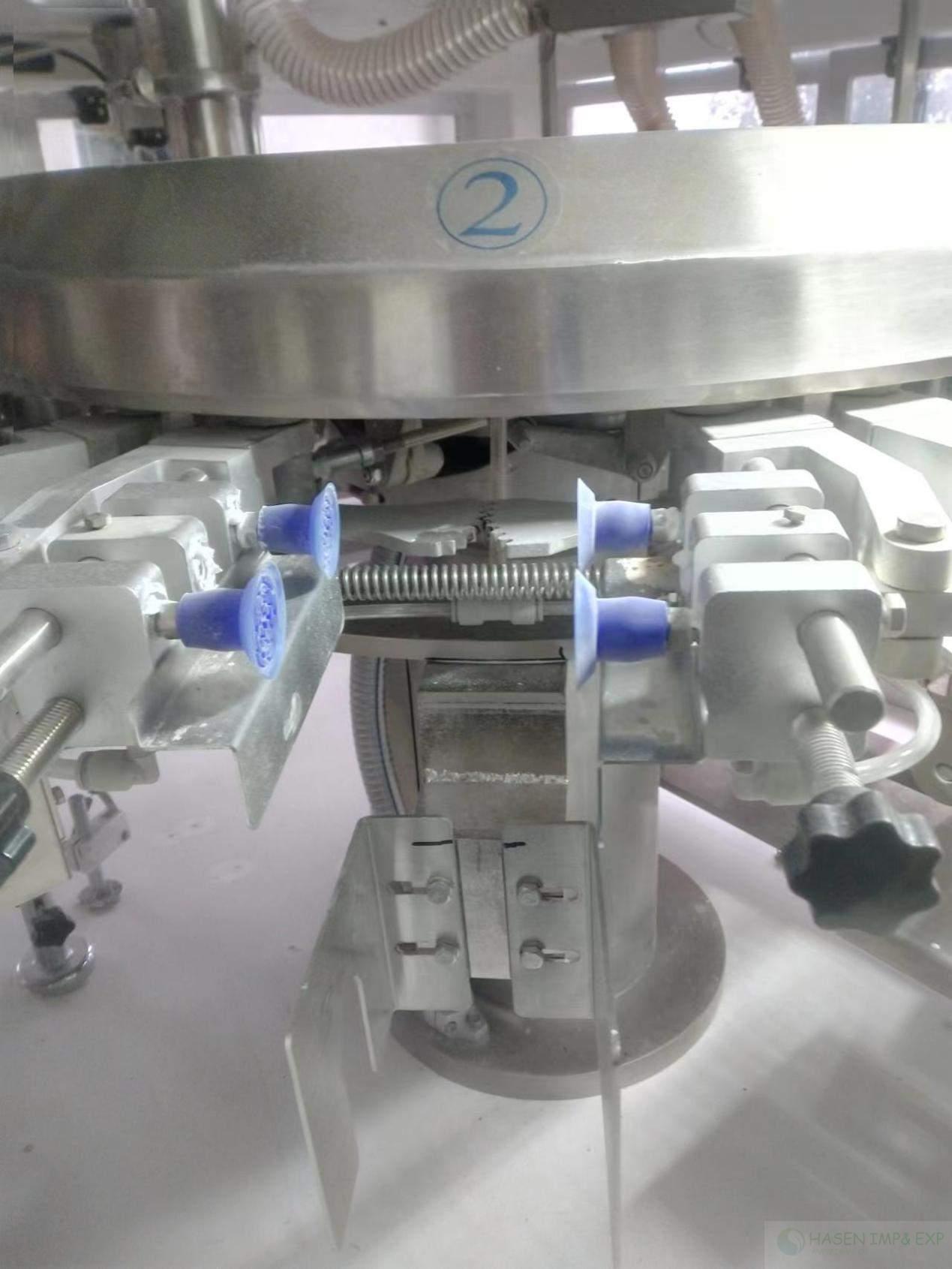

The bag station corresponds to the servo control between the front end of the bag silo and the bag suction cup, and the servo control bag supply manipulator; The bag opening station is the packaging bag running to this point, the packaging bag is fully opened, and the photoelectric switch is opened and checked, providing a feeding signal for the filling station, the packaging bag is opened for filling, otherwise it is not filled; There are many seismic stations to ensure that the materials can be fully shaken, and ensure the stability of the finished packaging shape.

The action of each station is controlled by the cam, the vacuum in the gripper is supplied by the vacuum chamber, the eight stations of the main turntable are exactly the same, and the lower part of the gripper is equipped with a pair of baffle plates, so that after the bag is filled with materials, it can ensure that the bag will not tilt or fall, and can operate normally on the vibration plate, and can make both sides of the packaging bag relatively flat and beautiful.

The outer edge of the main turntable is equipped with an arc-shaped baffle, which is also to prevent the deformation of the packaging bag during the rotation of the bag; The height of the baffle can be adjusted up and down according to the amount of material to ensure the effect of bag shape and shock.

Adjust

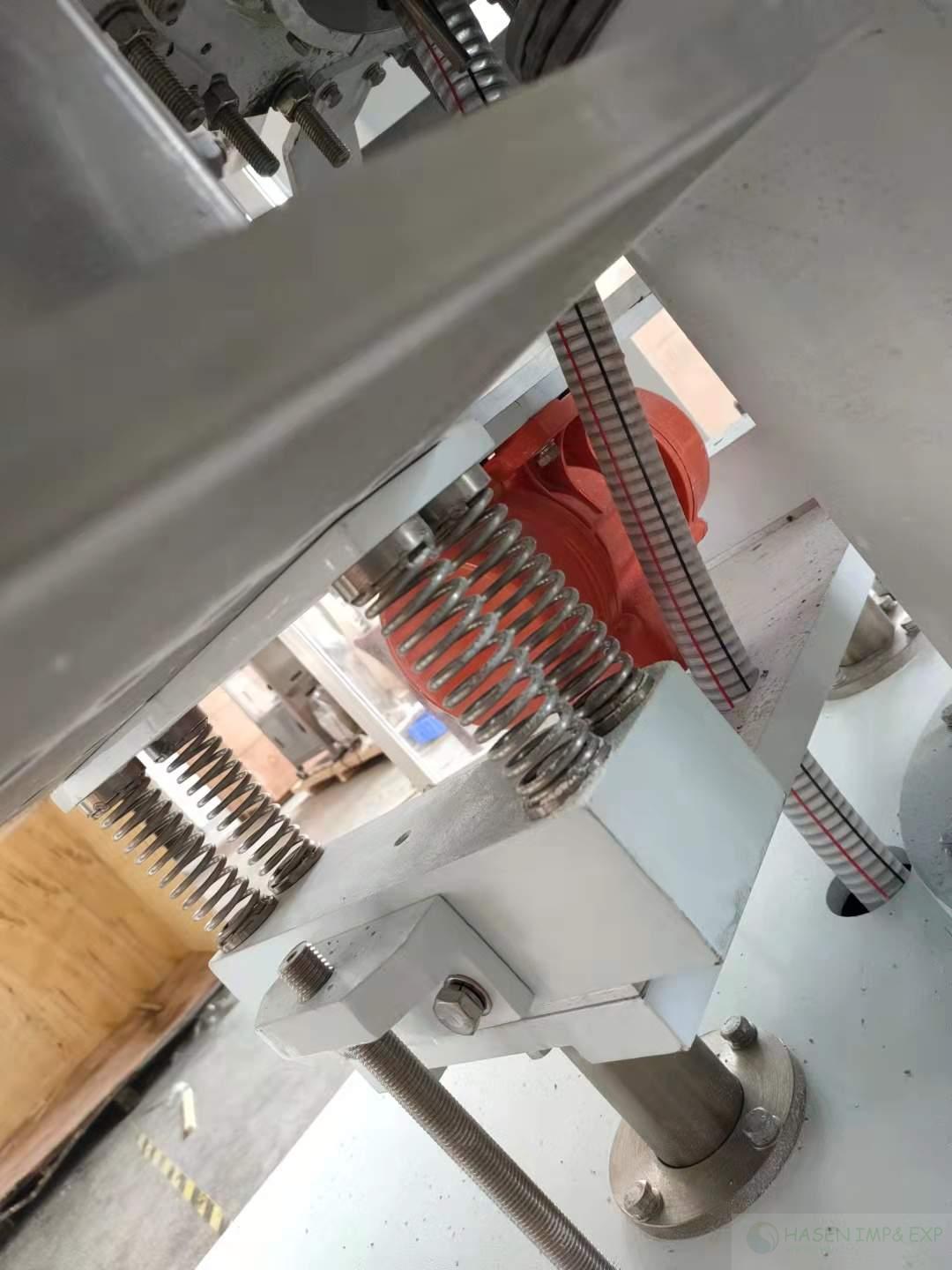

(1) Adjustment of large plate opening claws

This mechanism is a pure mechanical structure, is a combination of cam mechanism - rack and pinion mechanism - four-link mechanism, with cam control gear to drive the movement of the connecting rod, the gear then transmits the movement to the gear swing arm, adjusting the rod machine suction cup seat composed of four connecting rods, so that the suction cup seat moves parallel with the rotation of the gear; In this way, the opening and closing of the suction cup seat can be kept symmetrical and parallel; The suction cup on the suction cup seat completes the bag opening under negative pressure.

In the bag supply station, the position of the gear swing arm can be adjusted by the adjustment rod, so that the two gear swing arms are symmetrical, and the suction cups on the two suction cup seats can be closed, and the adjustment lever makes the suction cup mouth and the supply bag splint on a flat surface; Adjust the 8 stations with one button, so that each set of grippers is exactly the same, And the side width of the packaging bag is basically the same; According to the adjusted gear jaw size and position, adjust the size and position of the side baffle so that the size of the side baffle and the gear gripper are basically the same.

Structure diagram of large disc card bag claws

Folding M side mechanism

According to the picture above, the mounting seat of the upper and lower cylinders and the fixed seat of the pressure cylinder are fixed on the frame plate, the type mounting plate is fixed on the cylinder rod of the cylinder, the folding bag cylinder and the inner folding plate are fixed on the seat type plate, the outer folding plate is fixed on the piston rod of the cylinder, and the pressure head is fixed on the piston rod of the pressure port cylinder.

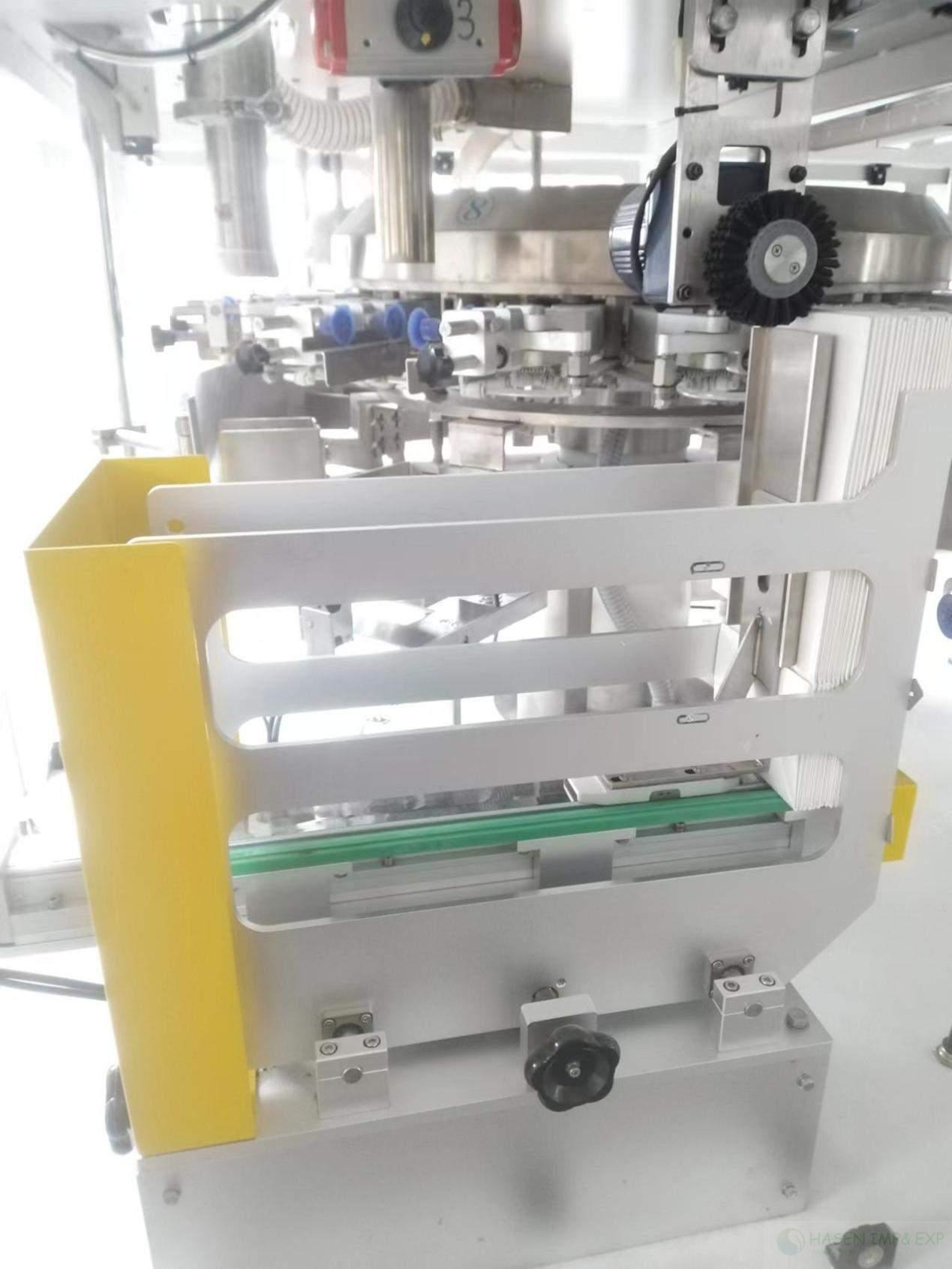

Bag transfer mechanism

As shown in the figure, the bag shifting jaw is fixed on the front and rear guide rails through the bracket, and moves back and forth through the cylinder, the upper part is driven by the shaft as a whole, and can slide left and right on the guide rail, which is a hook bag, the packaging bag is removed from the main plate, and the bag holding plate ensures that the bag type is stable during the movement of the bag, in the packaging of different specifications of materials and packaging bag type, the bag transfer mechanism should be appropriately adjusted according to the filling height of the material, with the left and right bag holding baffles on the large plate, so that the bag transfer claw can smoothly transfer the packaging bag from the main turntable to the bag mouth processing part behind.

Sealing compaction mechanism

As shown in the figure above, the entire bag mouth processing mechanism is distributed in turn, from left to right: cutting mechanism, folding machine, hammer edge mechanism, bag mouth inclination mechanism, glue spray drive mechanism, shaping and sealing mechanism. Each mechanism corresponds to the claw of the lower side transfer bag mechanism, and the whole fixed miscellaneous large plate, the large plate is lifted on the groove frame by the connecting rod, the groove frame is stuck in the guide groove, and the entire bag mouth processing part can be adjusted up and down through the connecting rod, and can be adjusted backward, backward, left and right in the guide groove. When the packaging bag comes from the folding bag mechanism, it enters the bag mouth processing mechanism through the guide plate, and when it moves to the cutting mechanism to stop, the cutting cylinder action begins to cut; At the same time, the rest of the mechanisms act separately to complete the folding edge, hammer edge, bag mouth tilting, glue spraying, and sealing action. When adjusting, the main adjustment of each cylinder action parameters, each mechanism is relatively independent, can jog each cylinder in the debugging interface, in the setting interface, according to the jogging situation appropriate adjustment.

According to the height of the bag, adjust the adjustment boom on the installation board to make the whole mechanism

Move up and down to the appropriate height, about 20 cm from the material. Adjust the upper rectangular groove frame,

The entire mechanism can be moved vertically so that the packaging material stops in the middle of the corresponding mechanism in the upper part. Before the overall linkage, the actions of each mechanism should be tested separately, and then linkaged after the entire action is coordinated.

Plastic surgery, incision height adjustment mechanism

Pocket holding movement mechanism

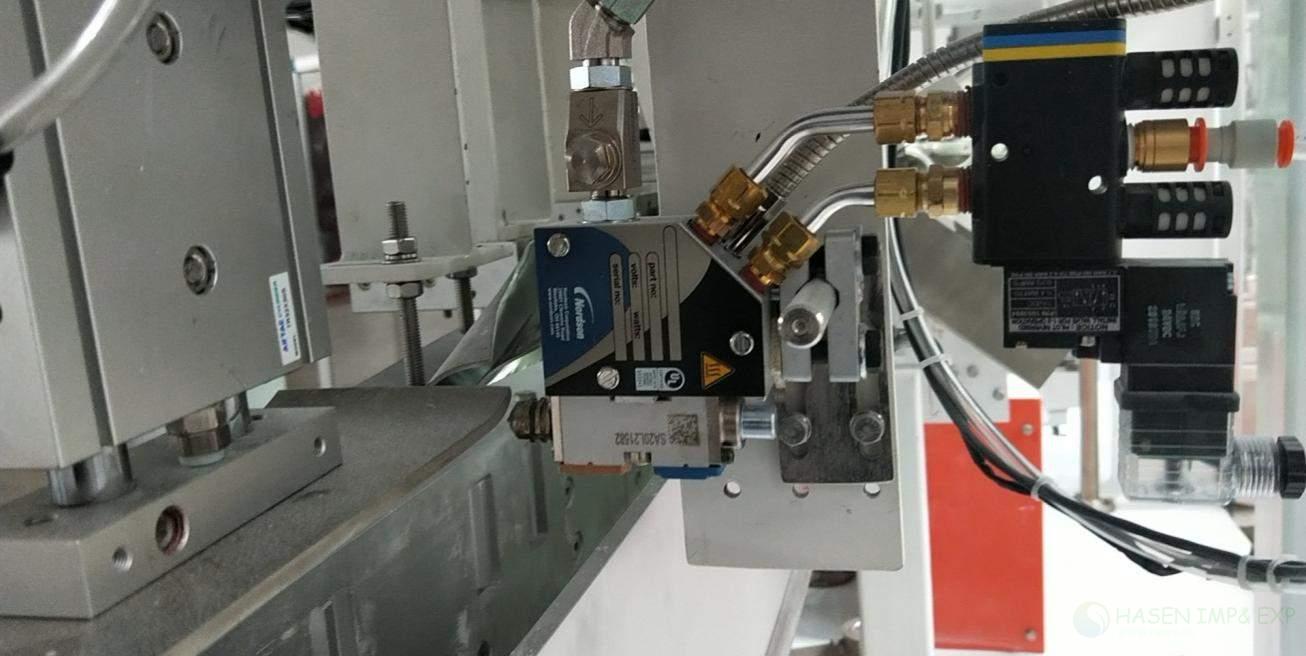

Glue Dispenser (Nordson)

The bag silo is driven by servo motor, which can put 200-300 bags at a time

Mobile guide rail sealing: reduce dust into the mobile guide rail, which is a smoother action of the whole machine;

Permutation counting mechanisms

Set the number of permutations through the touch screen, count by optical fiber photoelectric counting;

Sleeve film mechanism: according to the number of touch screen settings, the arranged products are packaged with PE plastic film\

Screw measuring machine

Screw Hoist

5 Equipment installation, delivery and warranty

Public works conditions

Power supply

AC 380V+10%〜-15% 50Hz±2%, three-phase five-wire system

Total power: 45KW

Air supply (air)

Pressure: 0.5-0.7Mpa;

Atmospheric dew point: -40°C;

Oil content< 0.01μm;

Dust content: <0.03μm;

Temperature:-10~+40(°C)

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:amina@immyhitech.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000